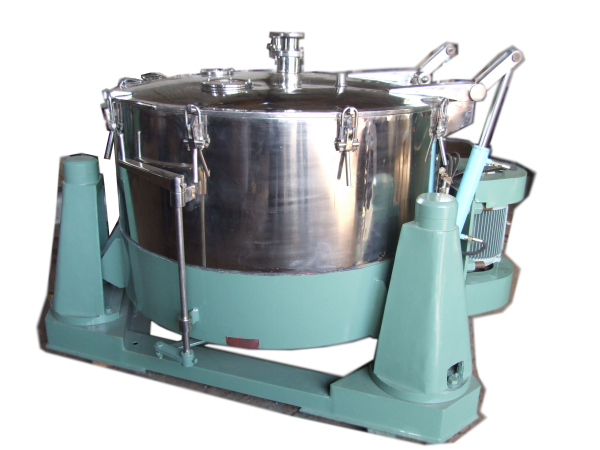

Bottom Discharge Centrifuges

Whirler Bottom Discharge Centrifuges offer reliable, clean, and efficient separation solutions for pharmaceutical, chemical, food, and fine chemical processing.

Whirler Bottom Discharge Centrifuges offer reliable, clean, and efficient separation solutions for pharmaceutical, chemical, food, and fine chemical processing.

Optimize your textile processing with specialized Whirler Hydro Extractors. Ideal for laundries, dyeing units, and garment manufacturers seeking efficient water removal.

Discover versatile laboratory basket centrifuges, including benchtop and pilot scale models, designed for precise and reliable separation in various lab settings.

Discover the versatility of our lifting bag discharge centrifuges, ideal for sensitive product handling in chemical, pharmaceutical, and food processing. Achieve superior product purity and simplified solids recovery across diverse applications.

High-performance manual top discharge centrifuges for chemical, pharmaceutical, and other industrial applications. Ensure precise separation with our reliable equipment.

Whirler’s Vertical Basket Centrifuges are engineered for high-performance solid-liquid separation across a wide range of industrial applications. From bulk chemicals and pharmaceuticals to food processing and textiles, these robust machines provide reliable and efficient dewatering and clarification. Featuring a simple, top-loading design, they are easy to operate and maintain. We offer various discharge methods, including manual top discharge, lifting bag, and bottom discharge, to meet your specific process requirements and ensure optimal product handling.

Explore our detailed presentation on Vertical Basket Centrifuges. This document provides an in-depth look at the features, benefits, and technical specifications of our centrifuge models, helping you understand how they can fit into your specific industrial processes.

To help us provide you with the most accurate and tailored information for your centrifuge needs, please download and fill out our Customer Information Collection Form. This allows our engineering team to better understand your specific application and requirements, ensuring we can offer the best possible solution.